As I mentioned in my previous post, a gentleman, who lives up the road from Jay and me, graciously gave us a rather large cutting board.

I’m going to try to avoid the fray when it comes to defining a cutting board. As you may be aware, there is a bit of a discrepancy when it comes to the whole “Cutting Board vs. Butcher’s Block” debate. Some say everything is a cutting board, while others claim anything can be used as a butcher’s block. I did find a good site that explained the three rules to identifying a butcher’s block. They are:

1. The board is constructed using only end grain.

2. The board is constructed to a thickness of at least 1.5 inches.

3. The board consists of enough surface area to adequately handle any meat you may wish to butcher (we say a minimum 12″ x 12″ surface).

Since our new cutting board wasn’t created using end grain, it only meets two of the three requirements to be considered a butcher’s block. It is one and a half inches thick though and has a surface area of 25 inches by 48 inches, so I’m willing to wager it’s original intended use was to butcher. Either that, or it was to be (or actually was) used as a counter top. I think I’d like to simply call it our giant cutting board. It’s great for prepping vegetables in the kitchen as well as using as a background for our culinary related photo shoots.

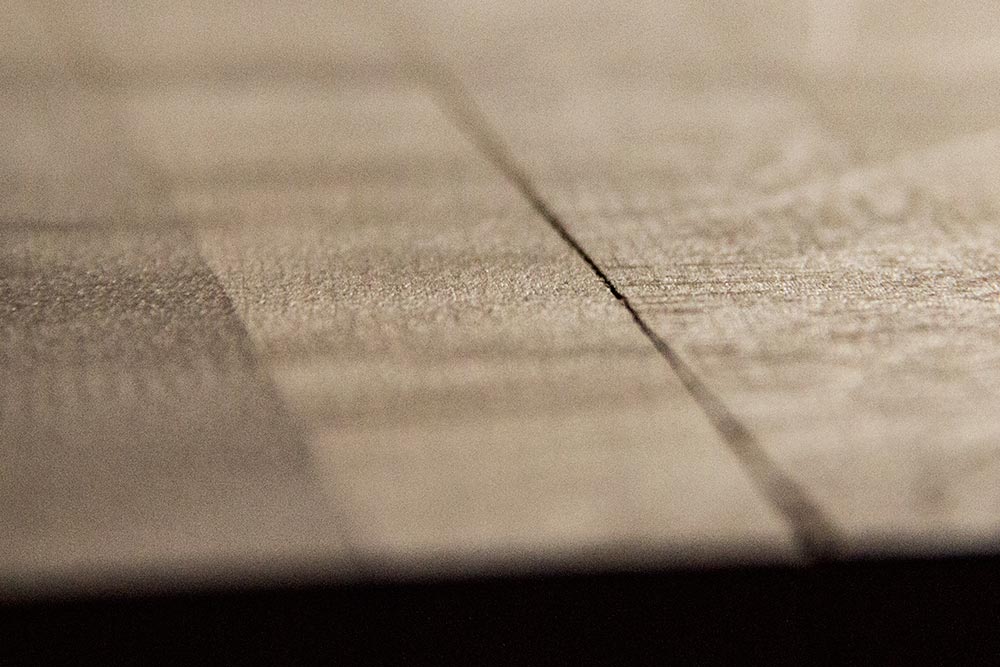

Our cutting board was stored in a woodworking shop for…I’m not sure how long. Most likely years and years. When we took possession of it about a week ago, it was in great shape, except for a few finger prints. I’d also say time has taken its toll on it, as the surface looked a bit dull. I’d love to show you some photos of the surface before I sanded it, but all I’m able to offer is some photos of the edges. I haven’t touched those yet.

Before Sanding & Finishing

Now that I think about it, I’m going to pretend that I haven’t sanded the surface yet. Since I only did a quick once-over with some 100 grit sandpaper, it’s almost like nothing has been done. I did manage to remove most blemishes from the surface though, so I am a bit of a fibber when I make this claim.

I just took a few shots of the edges and some of the surface of the board. These should give you an idea of what we’re working with.

Refinishing one of these boards really isn’t all too difficult. All that needs to be done is some sanding, followed by a coat or two of some food grade mineral oil. Initially, my idea was to limit the sanding to just the surface. The surface is all we need. But, after some consideration and after realizing I’m only going to get one shot at this, I decided that the surface as well as the edges need sanding. I’m not going near the bottom because no amount of sanding is going to help that side. And even with that said, I’m not going to go nuts with the edge sanding. I simply want to clean the board up a bit so it’s presentable.

Sanding the Board

I just went outside in my makeshift wood shop and did a bit of work. While I did smooth over the cutting surface once or twice, I primarily focused on the edges. There wasn’t anything particularly wrong with the edges – it’s just that they were dirty and old looking. As long as I’m busy sprucing up the rest of the board, I found time to clean them up as well.

In this photo, you can see the board resting with a hand sander on top, just waiting to be groomed.

As you can see from this next photo, just a bit of sanding can really make a difference in cleaning up a dirty edge.

This is my attempt at being artistic. I saw some nice lighting and some saw dust, so I had at it. Those elements, along with some very narrow photographic depth of field, made for an elegant photograph.

Uh oh. We’ve got problems. I actually noticed the ends of our board splitting during the earlier photo shoot. Looks like this post is going to be a bit longer, with a section dedicated specifically to repairing splits (or cracks) in a cutting board. These are most likely caused by age, lack of care and a sharp change in humidity. I brought the board inside a warm house from an unheated workshop.

Repairing the Split Ends

I took a closer look at the board and noticed quite a few seams that are apparently coming undone. I’m not sure why this is, but I’ve devised a plan to repair the splits. First, let’s see what I’m up against.

As you can see, things are getting a bit loose.

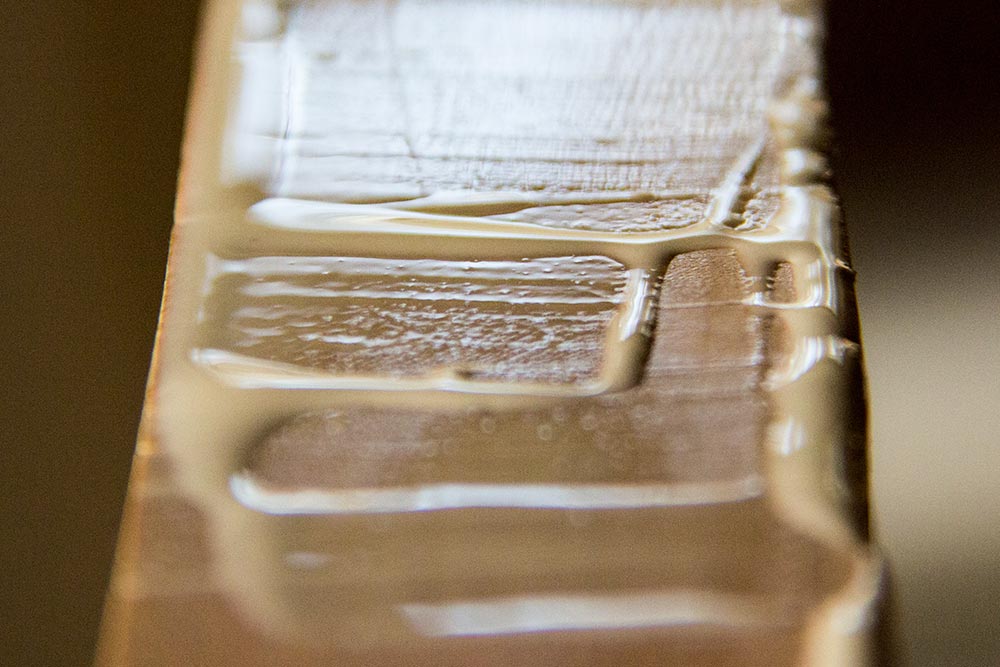

This morning, I took a trip over to the hardware store in town and picked up some “Titebond 3” wood glue. According to the woodworking world, this is the glue to use to construct or repair a wooden cutting board. There are a few reasons for this. First, it’s water proof. Second, it’s as strong as all get out. Third, it’s non-toxic and safe for indirect food contact and fourth, it’s fairly thin, meaning, it’ll settle into cracks nicely. As a matter of fact, as I write this post, I’m checking on the backside of the board and continuously filling any splits that I see the glue has seeped into. I’d like it to get in as deeply as possible and for each split to hold as much material as possible.

The glue cost $9.99 for a 16 fluid ounce bottle.

Since I wasn’t sure of the best way to go about getting as much glue as I could into all the tiny crevices, I thought a nice, liberal application was in order.

I did have an idea though. I thought that by using a drywall spackle, I’d be able to really press the glue into the cracks. I tried it and it worked. I got as much glue in there as I could.

I debated with myself over whether or not I wanted to clamp the board in an effort to press each strip of wood back together again. I decided against it because, in the past, I’ve attempted stunts like this and only ended up with more damage than I began with. I simply wiped off the excess glue with a wet towel instead.

In the photo above, you can see that the glue hasn’t dried yet, but I think it looks pretty good. My only alternative was to pull the entire board apart, re-plane each piece and glue it all back together again, as if I was initially constructing it. In the future, I may do that, but for now, it’s fine.

Oiling the Board

After letting the glue in the cutting board dry overnight, it was ripe to be oiled. In case you aren’t aware, massaging oil into the wood is the final step in my repairing and refinishing of this work of wonder. Good thing too, because this little project has turned into a three day ordeal. I just hope everything stays together for years to come. I’ve gotten somewhat attached.

Anyway, a few days ago, I picked up a bottle of “Howard Cutting Board Oil.” It consists of food grade mineral oil. I did some research on what types of oils are recommended for reconditioning wood like this and food grade mineral oil is pretty much the only way to go. Olive oil and other vegetable oils are out because they become rancid. Other types of oils are also out because they’re toxic. Even less refined mineral oils can’t be used because they aren’t processed to the point of being safe around food.

I think I paid around $8.99 for 12 fluid ounces of this oil.

And as you can see from the photo above, I’m using an old cotton polishing rag to apply it.

Basically, I just drizzled the oil onto the board and rubbed it in. If some spots needed more, I applied more. It didn’t take much at all to complete everything. Once the rag gets enough oil in it, I didn’t need to drizzle any more onto the board.

Once that was finished, I had my final product. Wood looks so much better after the finish is applied. Now, I can begin practicing my knife skills on it and Laura can begin using it as a set for some food photography.

——

If you’ve enjoyed today’s post and found it helpful, please share it with a friend. Also, if you’d like to continue reading and would like my posts sent directly to your email inbox, simply sign up for my newsletter. I’ll send each and every post directly to you. Thanks!

Leave a Reply